Introduction:

As sustainability becomes an increasingly important factor in client picks, the eyewear industry is stepping up its game by embracing eco-friendly practices. Daposi Eyewear, a trailblazer in the eyewear market, is at the forefront of this movement with its commitment to creating recycled plastic sunshades. In this text, we will delve into the science behind the recycling technique, shedding light on how Daposi Eyewear transforms discarded plastics into elegant and sustainable sun shades.

The Plastic Problem:

The ubiquity of plastic in our everyday lives has led to an environmental disaster, with considerable amounts of plastic waste polluting oceans and landfills. Recognizing the urgency of this trouble, Daposi Eyewear has taken a proactive approach to cope with the plastic problem by incorporating recycled materials into its shades.

Collection and Sorting:

The first step in the recycling method entails collecting and sorting plastic waste. Daposi Eyewear collaborates with recycling centers that cautiously categorize plastics based totally on their resin types. This meticulous sorting is critical for retaining the integrity of the recycled cloth.

Cleaning and Shredding:

Once taken care of, the collected plastic is very well wiped clean to remove any contaminants. The wiped clean plastic is then shredded into small pieces, growing what is referred to as "flakes". Daposi Eyewear places exquisite emphasis on the cleanliness of the plastic to ensure that the very last product meets extraordinary requirements.

Melting and Purification:

The shredded plastic flakes go through a melting method to transform them into a molten form. During this phase, impurities are eliminated, and the plastic is purified. Daposi Eyewear's commitment to first-class quality shines through the meticulous purification method, ensuring that the recycled material meets stringent requirements for sunglasses production.

Extrusion and Pelletization:

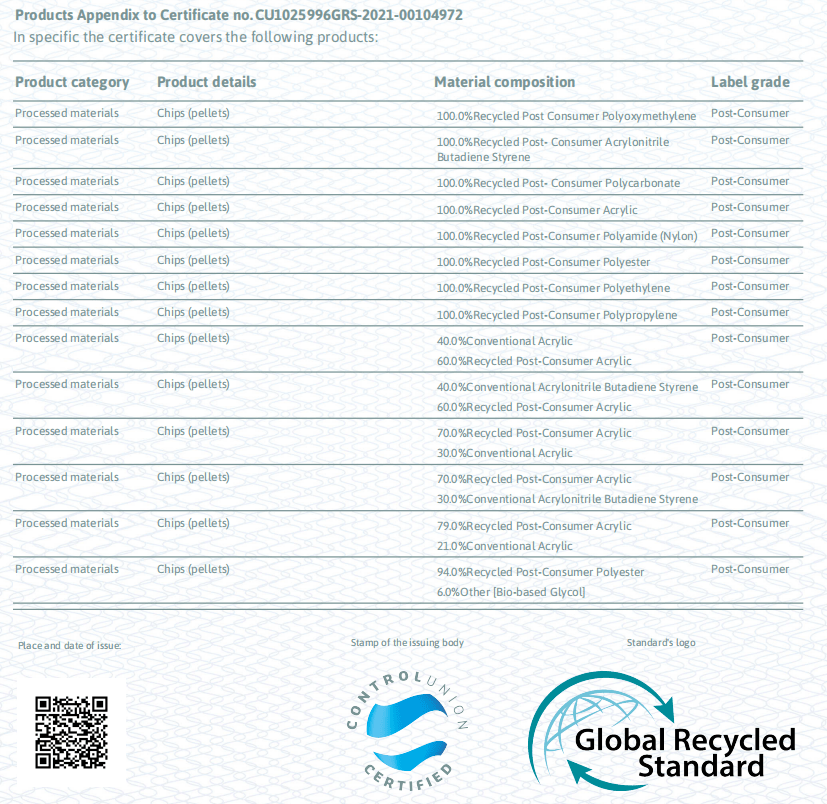

The purified molten plastic is then extruded into skinny strands, which are subsequently reduced into small pellets. These pellets function as the raw material for crafting the frames of Daposi Eyewear's recycled plastic sunglasses. The extrusion and pelletization system is a vital step in ensuring that the recycled plastic meets the brand's specifications for power, flexibility, and aesthetics.

Frame Manufacturing:

Daposi Eyewear employs modern-day technology to mold recycled plastic pellets into elegant and durable sunglass frames. The brand's dedication to precision in production ensures that each frame not only meets but exceeds industry requirements for each form and characteristic.

Lens Production:

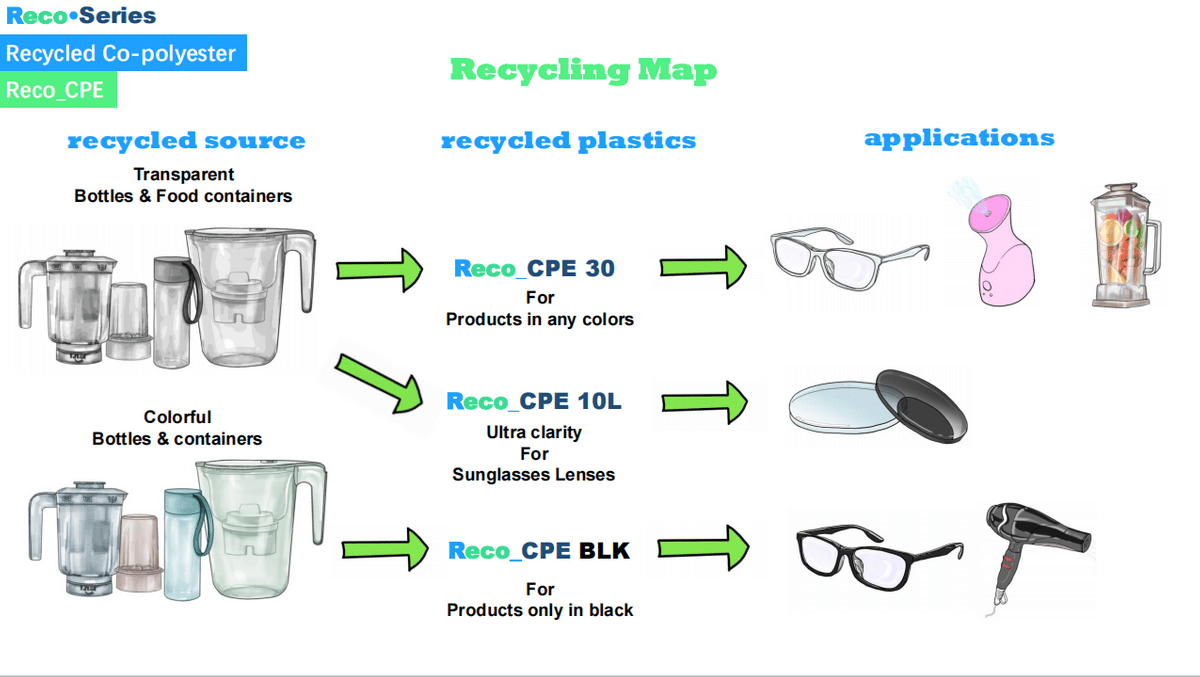

In addition to the frames, Daposi Eyewear can pay interest on the lenses, incorporating sustainable practices into this issue of sunglass manufacturing. The emblem explores substances like recycled glass or plant based options for lens production, further lowering its environmental footprint.

Assembling the Sunglasses:

The frames and lenses are meticulously assembled to create the very last product – a couple of recycled plastic shades that not only meet the highest standards of quality but also contribute to environmental conservation.

Quality Control:

Daposi Eyewear places a robust emphasis on exceptional management during the manufacturing process. Rigorous testing guarantees that the recycled plastic sun shades aren't only elegant but also durable, providing clients with eyewear that stands the test of time.

Eco-Friendly Packaging:

The commitment to sustainability extends beyond the sunglasses themselves. Daposi Eyewear adopts a holistic technique with the aid of eco-friendly packaging substances, minimizing the environmental effects related to product packaging.

Closing the Loop:

Daposi Eyewear embraces the concept of a round economy of encouraging clients to participate in the recycling procedure. The brand allows the go back and recycling of antique sun shades, finishes the loop and ensures that the life cycle of its products is environmentally responsible from start to finish.

Educating the Consumer:

A vital component of Daposi Eyewear's method of sustainability is instructing consumers about the environmental effects of their alternatives. The logo emphasizes the importance of recycling and making eco-conscious decisions, empowering clients to make contributions to advantageous alternatives.

Conclusion:

Daposi Eyewear's commitment to creating recycled plastic shades is not just a reflection of fashion-forward thinking; it is an ambitious step closer to mitigating the environmental effect of plastic waste. By knowing the intricacies of the recycling method, purchasers can respect the technology in the back of Daposi Eyewear's sustainable eyewear and make informed choices that align with their values.

As the fashion industry evolves, Daposi Eyewear stands as a beacon of innovation, proving that fashion and sustainability can coexist seamlessly. The technology of recycling has in no way seemed so fashionable – thanks to Daposi Eyewear's determination to transform plastic waste into eco-friendly style statements.